Pneumatic conveyor for metallurgy

2024-08-16 10:36:47

Pneumatic conveyors for metallurgy are specially designed for the production and transportation of solid and wet concrete mixtures and refractory concrete. It is not only suitable for the metallurgical industry, but also for the concrete pouring of structures such as water channels and drains in steel production, as well as the concrete construction of various containers, covers, etc. in steel plants. It is also widely used in the construction industry for pouring foundations, floors and large-area concrete of buildings.

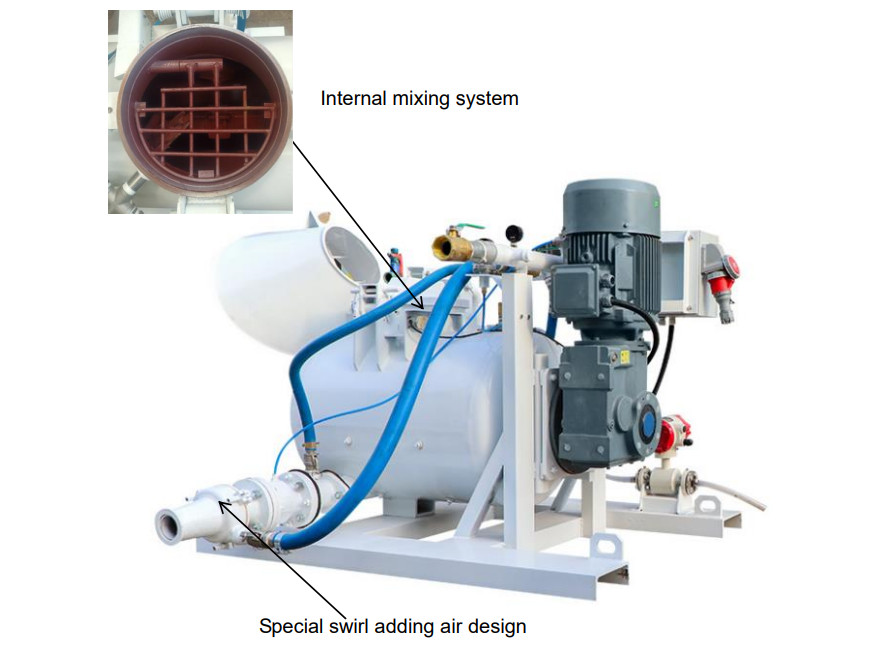

The mixture enclosed in the pressure tank will be mixed by the movement of the mixing blades and compressed air. The mixing blades slide the mixture at the same time and push it into the discharge port of the tank. In addition, the lower compressed air enters the conveying hose, blowing the mixture to move evenly in the conveying hose. The mixture is conveyed in the conveying hose in the form of lumps, and the unique swirl gas path design prevents the material from fluctuating greatly.

The structure of the pneumatic refractory conveyor and the layout design of each component facilitate daily maintenance and repair, which helps to improve the overall reliability of the machine. This design feature ensures that the machine can still maintain stable performance under long-term high-intensity working conditions, reduce downtime caused by failures, and improve production efficiency and economic benefits.

Features of pneumatic mixing and conveying for metallurgy:

1. Efficient mixing and conveying system: It adopts advanced mixing technology to ensure uniform concrete mixture and stable quality. At the same time, it is equipped with an efficient conveying system to quickly and accurately deliver concrete to the designated location.

2. Durable materials: Considering the abrasiveness of concrete mixture, the key components of the machine can be made of high-strength and wear-resistant materials to extend the service life of the machine.

3. Flexible configuration: According to different construction needs, the machine may have a variety of configuration options, such as adjustable conveying distance, different mixing ratios, etc., to meet the construction requirements of different occasions.

4. Easy maintenance: As mentioned above, the structure and component layout of the machine are designed for easy maintenance. Including easily accessible maintenance points, detachable components and clear maintenance manuals to reduce maintenance costs and improve maintenance efficiency.

5. High reliability: Through optimized design and strict quality control, the machine can maintain stable performance and high reliability in harsh working environments.

In summary, this pneumatic refractory mixing and conveying unit designed for manufacturing and conveying concrete mixtures has a wide range of applications in both metallurgy and construction industries. Its high efficiency, durability, flexibility and reliability make it an indispensable and important equipment in these industries.

Phone/Wechat

Phone/Wechat ADDRESS

ADDRESS