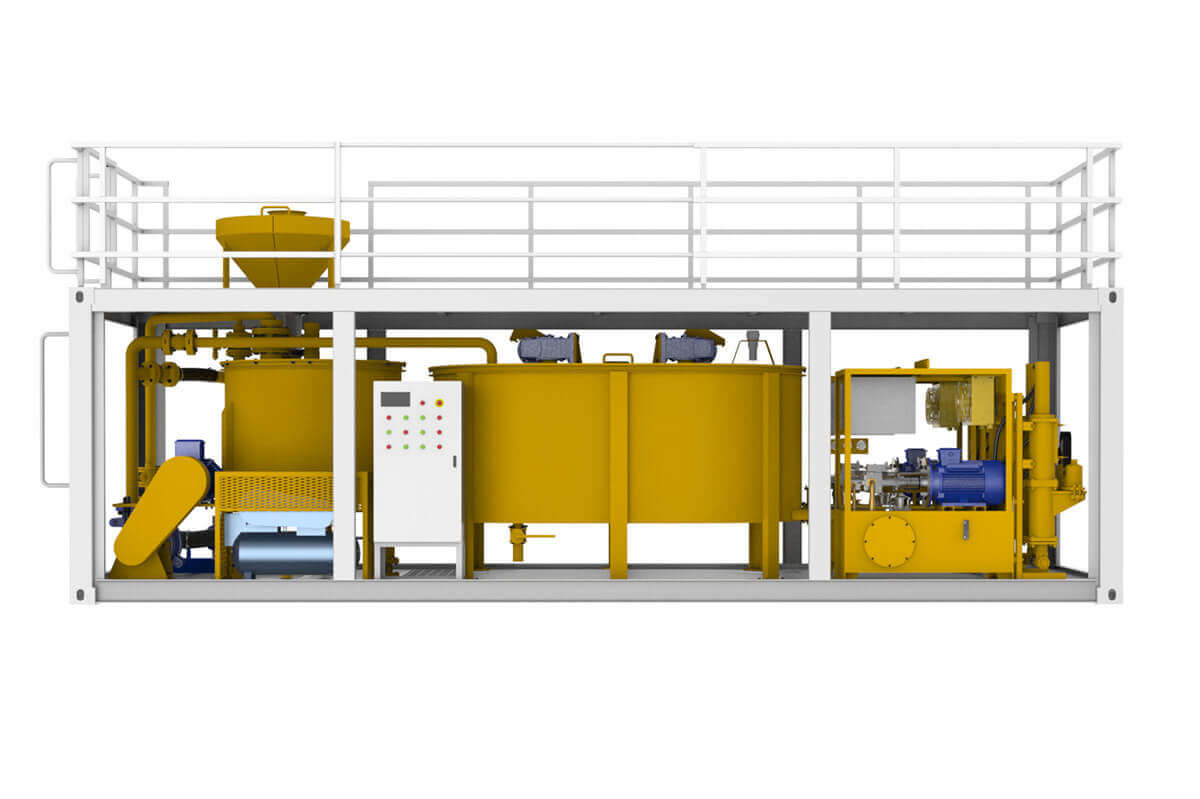

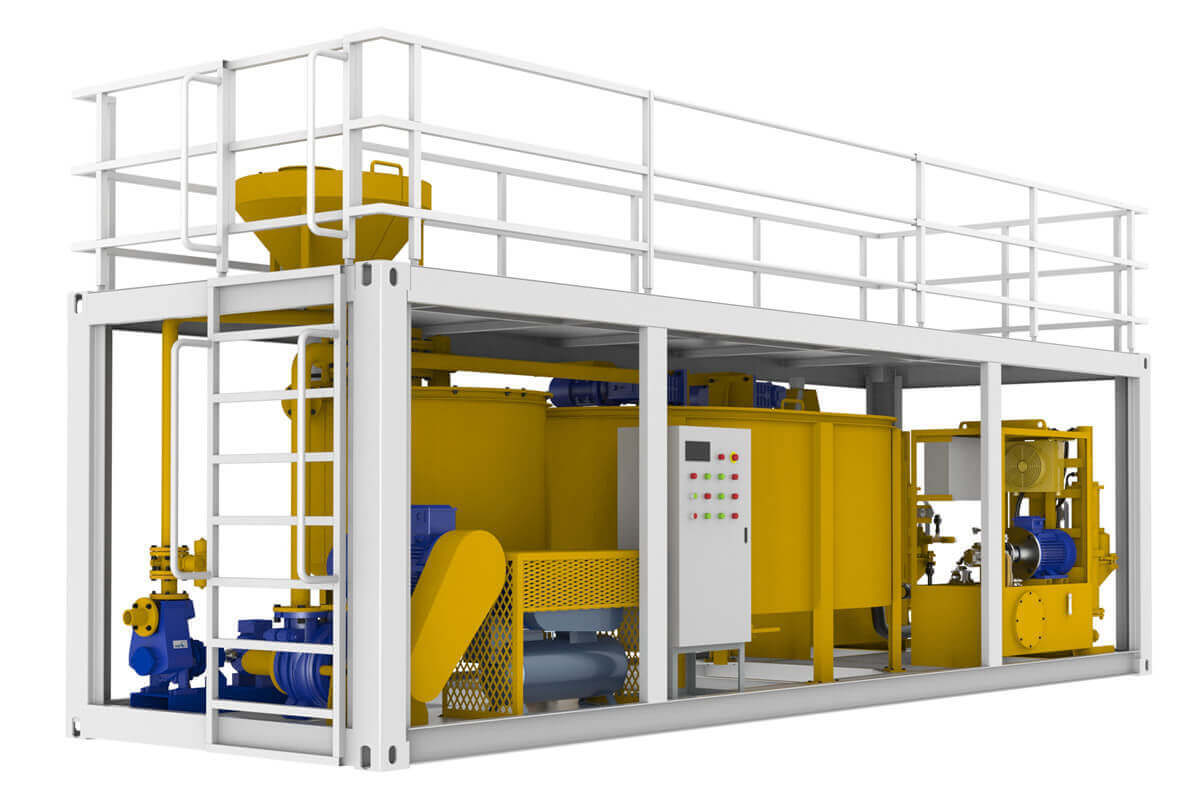

Automatic colloidal grout mixing station

2024-08-10 11:24:04

An automatic colloidal grout mixing station is a specialized piece of equipment used in construction and civil engineering. The automatic colloidal grout mixing station is designed to produce cement mixtures (cement grout) or bentonite slurries through high turbulence mixing. It combines water with cement powder to create a cement mixture, or water with bentonite powder to produce a bentonite slurry suitable for plastic muds. The station can also prepare ternary or quaternary compounds, utilizing one or two liquid components along with one solid component. Once mixed, the cement mixture or bentonite slurry is transferred to other units using a plunger pump (with two options available), based on the requirements of the geotechnical application.

1. Mixer: A high-speed, high-shear 1000L capacity grout mixer designed to blend the grout components thoroughly.

2. Agitator: A 4000L capacity grout agitator, agitator, slurry pump and agitator have an automatic cleaning function

3. Pumps: Equipped with 2 plunger grouting pumps, pressure: 0-3MPa, Flow: 2×(0-10m³/h), output and pressure can be step-less adjusting.

It can be placed directly in the 40ft cabinet.

Functionality:

1. Automatic Mixing: The station automates the mixing process, ensuring consistent grout quality and reducing the need for manual labor.

2. Precise Proportions: It accurately measures and mixes the grout components according to the specified ratios.

3. High Efficiency: Capable of producing large volumes of grout quickly, which is beneficial for large-scale construction projects.

4. Customization: Settings can be adjusted based on the specific requirements of the grout being used, such as its density and viscosity.

- Construction: Used for filling voids in foundations, anchoring bolts, and stabilizing soil.

- Mining: For ground support and stabilization.

- Civil Engineering: For repairing and reinforcing structures.

Overall, an automatic colloidal grout mixing station enhances efficiency, consistency, and quality in grout applications, making it a valuable tool in many industries.

Phone/Wechat

Phone/Wechat ADDRESS

ADDRESS