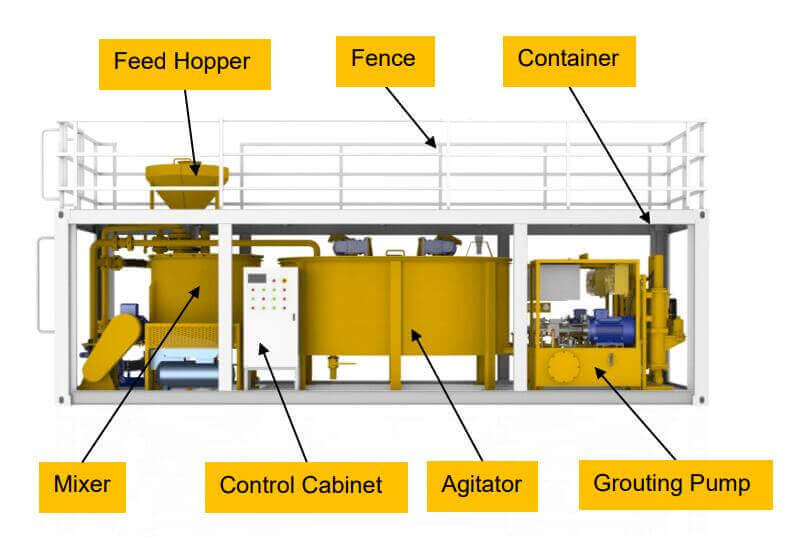

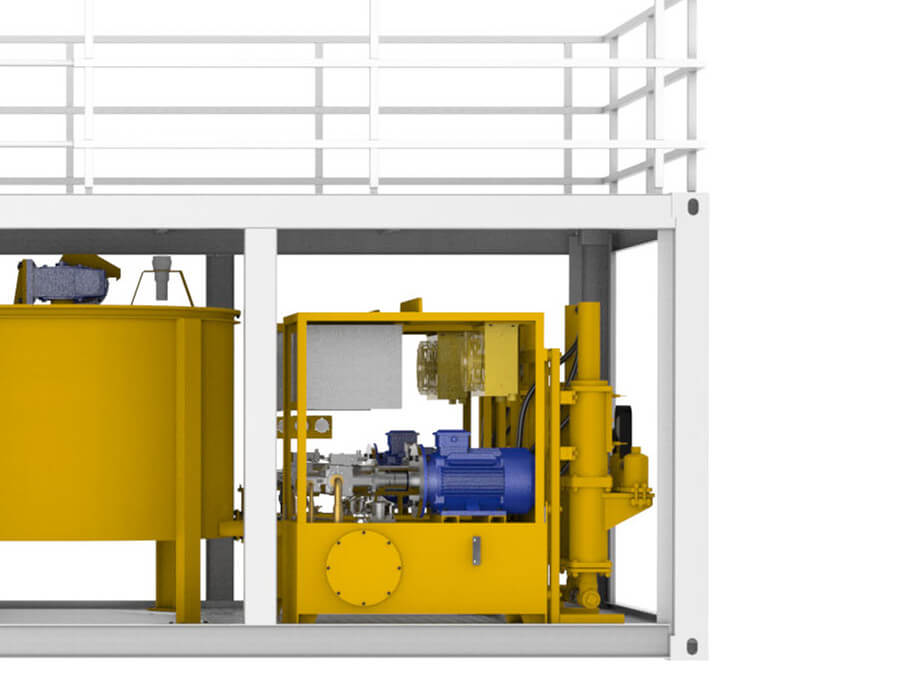

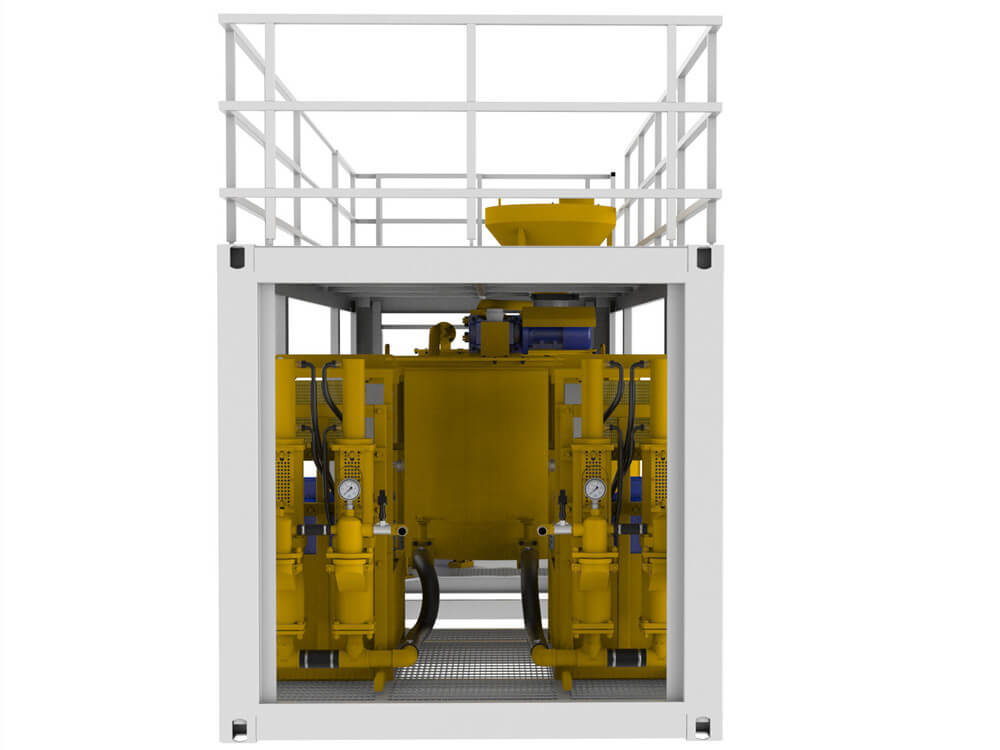

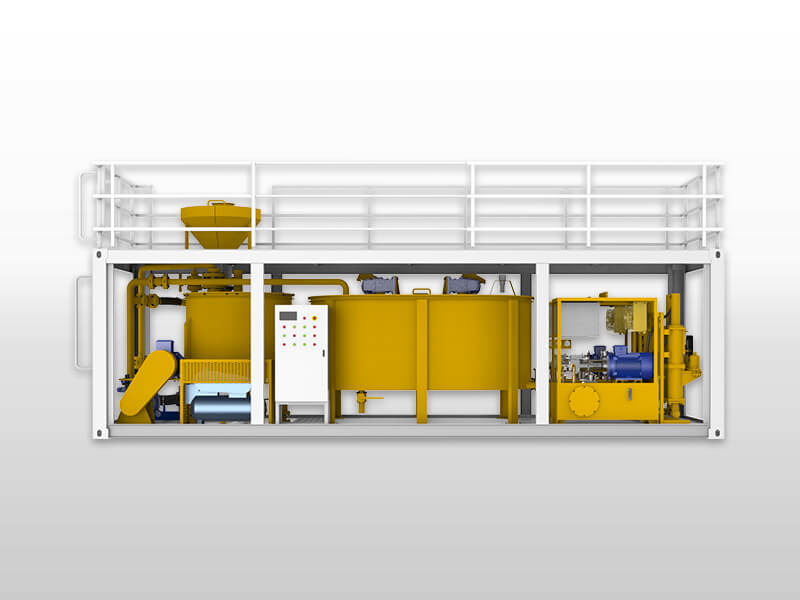

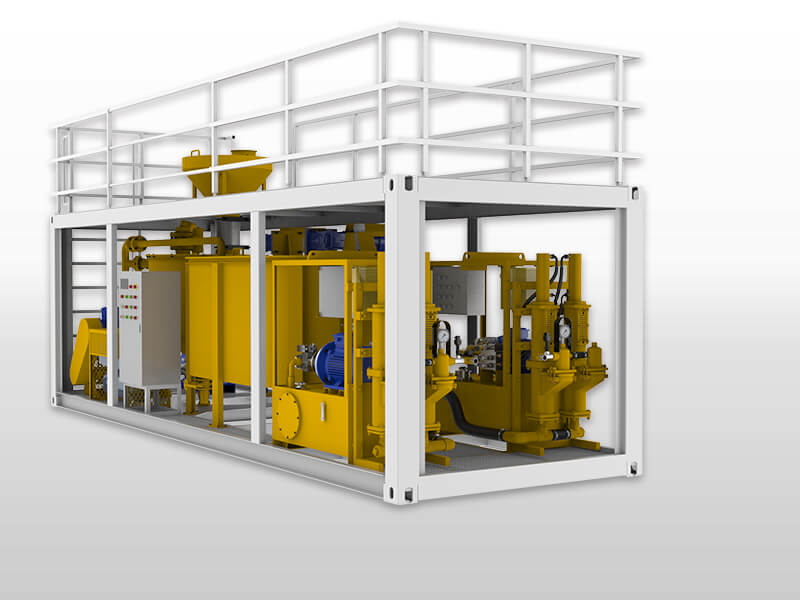

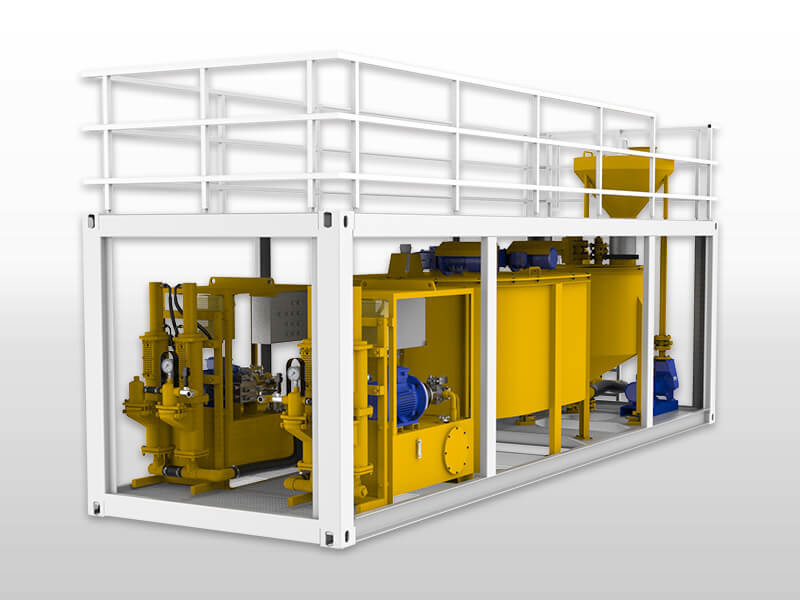

LGP1000/4000/2x165/30PL-E Automatic grouting pump with mixer is primarily designed to create a high-turbulence mixture of water and cement powder, resulting in a cement grout. Alternatively, when water and bentonite powder are used, it produces a bentonite slurry suitable for forming plastic muds. The system can also prepare ternary or quaternary mixtures, incorporating one or two liquid components along with a single solid component.

► Application:

LGP1000/4000/2x165/30PL-E Automatic grouting pump with mixer was primarily designed to produce high-turbulence mixtures of water and cement powder, creating a cement grout. Alternatively, when water and bentonite powder are used, it can produce a bentonite slurry suitable for forming plastic muds. The system is also capable of preparing ternary or quaternary mixtures, which may include one or two liquid components along with a solid component.

Once the cement grout or bentonite slurry is prepared, it is transferred to other units via a plunger pump (with two options available) based on the specific requirements of the geotechnical application.

This containter type automatic grout station / plant is suitable for a wide range of applications, including:

1. Anchoring: Used in the installation of rock bolts or soil nails where cement grout is injected to anchor the elements securely.

2. Sleeve Pipe Grouting: For grouting around pipes or tubes to ensure proper sealing and stability.

3. Contact Grouting: Involves injecting grout directly into the contact zone between different structural elements, such as concrete slabs and foundations.

4. Backfill Grouting: Used to fill voids behind walls or in the space between a structure and the surrounding earth to provide support and prevent movement.

5. Preparation and Pumping of Bentonite Suspensions: Ideal for pipe jacking and microtunneling operations, where bentonite slurry is used to stabilize the soil and facilitate the installation of pipes.

Automatic grouting pump plant/ station offers a flexible solution for various construction and civil engineering projects, making it a valuable asset for contractors and engineers who require precise and efficient grouting and slurry applications.

► Features:

1. Up to 5mm particle size

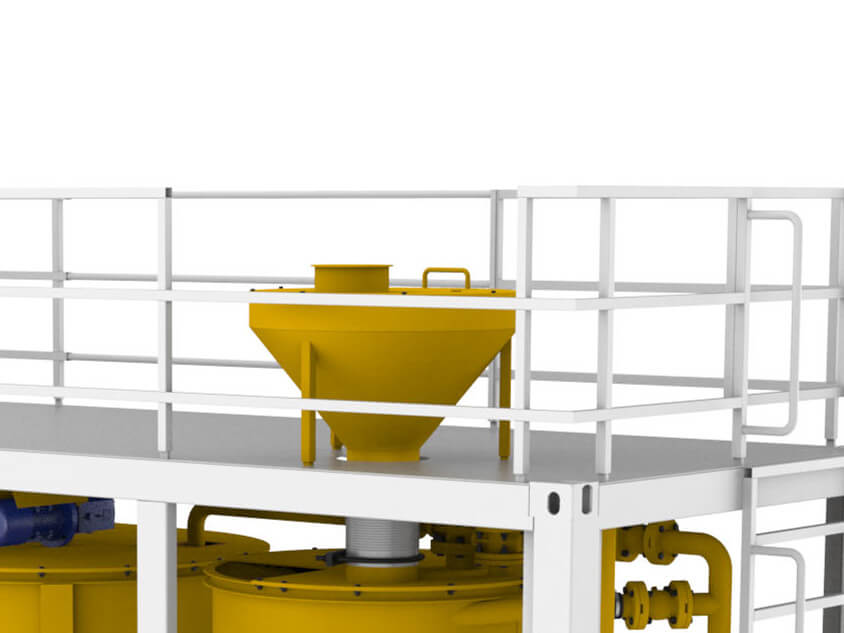

2. High-speed colloidal grout mixer

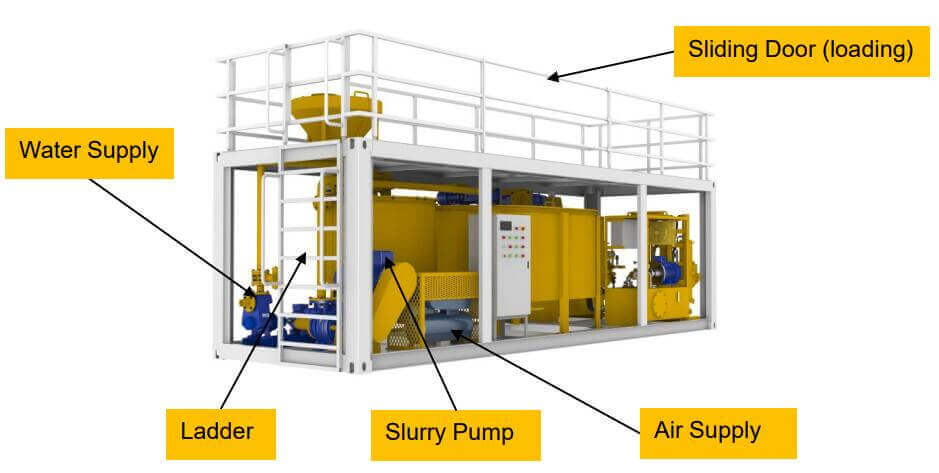

3. Can be placed directly in the 40ft cabinet

4. Main pipeline valves are all pneumatic valves

5. Output and pressure can be step-less adjusting

6. Cement can be added by screw feeder automatically

7. Mixer, slurry pump and agitator have automatic cleaning function

8. Two modes of operation:fully automatic mode and manual mode

9. High productivity due to ergonomically positioned operating elements

10. Equipped with some ceiling lamps, for illuminating the different working areas

11. High reliability and low-maintenance operation with good accessibility to the wear parts

12. Independent of pressure ratios, the suction stroke is always carried out at high velocity in order to flush the valves and to avoid clogging

13. The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components

|

LGP1000/4000/2x165/30PL-E Automatic grouting pump with mixer specification: |

|||

|

1. Two modes of operation:fully automatic mode and manual mode. |

|||

|

LGP1000/4000/2x165/30PL-E Automatic grouting mixer pump |

|||

|

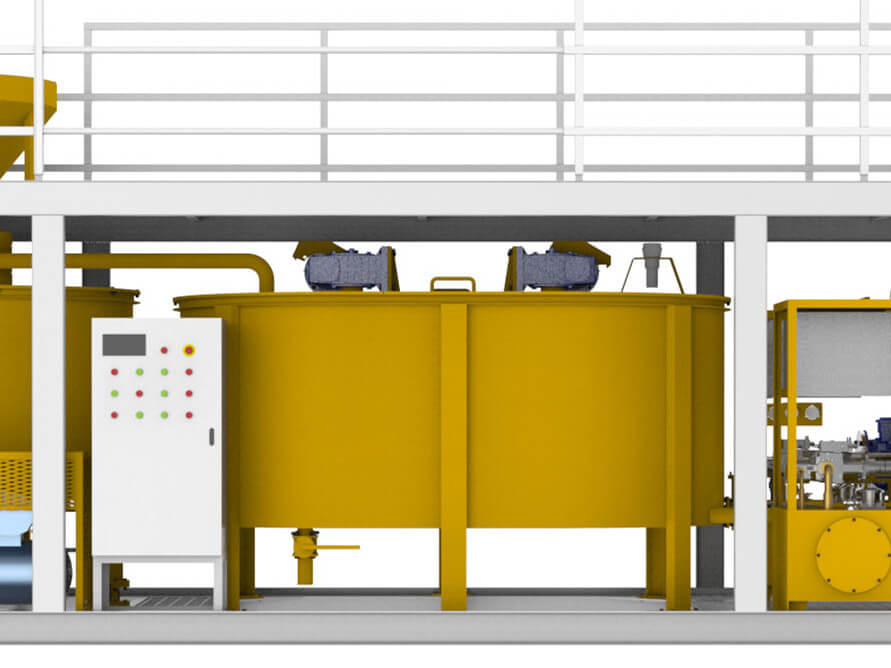

Mixer |

Agitator |

||

|

Volume |

1000L |

Volume |

4000L |

|

Flow |

1200L/min |

Speed |

36r/min |

|

Max. output |

20m³/h |

Level sensor |

Ultrasonic sensor |

|

Power |

15Kw |

Power |

2×3.0Kw |

|

Air supply system |

Water supply system |

||

|

Flow |

280L/min |

Flow@Lift |

5.6L/s@30m |

|

Power |

2.2Kw |

Power |

4.0Kw |

|

Grout Pump |

|||

|

Pressure |

0-3MPa |

Plunger |

120mm |

|

Flow |

2×(0-10m³/h) |

Plunger stroke |

200mm |

|

Oil tank |

2×180L |

Cylinder bore |

80mm |

|

Power |

2×15Kw |

Cylinder rod dia. |

45mm |

|

Size@Weight |

7200mm(L)×2200mm(W)×3160mm(H)@8.5t |

||

|

Power supply |

380V, 50Hz |

||

|

Note: |

|||

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

.jpg)

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS