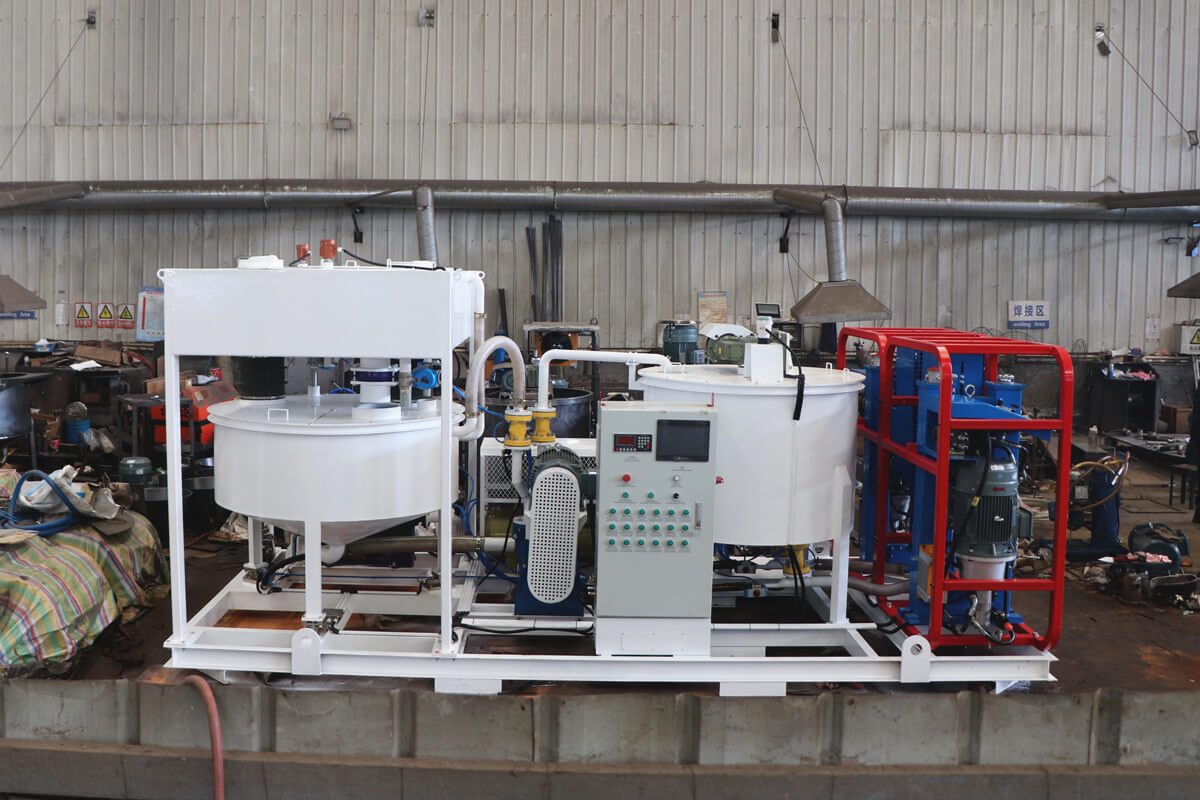

LGP1200/1200/2X75/100PI-E Automatic colloidal grout mixing plant is a combination of 1200L capacity mixer, a 1200L capacity agitator, a circulating pump and two high pressure vertical grouting pumps in one frame, it is very easy to operate and move.

LGP1200/1200/2X75/100PI-E Automatic colloidal grout mixing plant is a selection of jet grout plants with volumetric flow rates from 0 to 75L/min. The automatic colloidal grout mixing plant is integrated with the distributor, PLC, can freely adjust the proportion of water, cement, and additives, and can be set according to the formula of automatic configuration of materials, greatly improving the work efficiency.

Working principle of LGP1200/1200/2X75/100PI-E Automatic colloidal grout mixing plant:

Water and cement are quickly mixed into a uniform slurry. High-speed eddy current mixer ensures fast and even mixing. It enables high mixing capacity due to short mixing time. Automatic grouting plant is specially designed for cement and water-mixed projects. Its advantage is continuous mixing and grouting. The mix tank is for fast mixing. The grout is then transferred to the grouting pump, which ensures continuous mixing and grout operations. There are two operation modes: automatic mode and manual mode.

Details Instructions of LGP1200/1200/2X75/100PI-E Automatic colloidal grout mixing plant:

► Application:

LGP1200/1200/2X75/100PI-E automatic colloidal grouting plant is mainly used for making cement slurry, etc., which is applied for dam injection applications, tunnel applications, anchor injection, jet grouting, drilling, cavity filling, bottom injection, etc.

► Features:

1. There are two operation modes: automatic mode and manual mode.

2. It can realize automatic configuration and replenishment of materials.

3. The proportion of materials in the formula can be adjusted freely.

4. Flameproof electric cabinet, protection grade IP56.

5. High-speed vortex mixer ensures mixing quickly and evenly.

6. With CE and ISO certification.

7. Automatic colloidal grout mixing plant has compact structure.

8. Colloidal grout mixing plant is simple operation and easy maintenance.

9. Less spare parts ensure low maintenance costs.

| Name | Data | |

| Model | LGP1200/1200/2X75/100PI-E Automatic colloidal grout mixing plant | |

| Mixer | Capacity | 1200L |

| W/C ratio | 0.5~1 | |

| Agitator | Capacity | 1200L |

| Power | 3.0Kw | |

| Circulation pump | Power | 15KW |

| Rate Rev. | 1800r/min | |

| Flow | 850L/min | |

| Screw feeder | Power | 7.5KW |

| Delivery volume | 40t/h | |

| Water supply | Tank capacity | 950L |

| Water pump | 50ZX20-30 (4.0KW) | |

| Flow@head | 20m3/h@30m | |

| Additive supply | Tank capacity | 150L |

| Additive pump | 25SFBX-8 (0.25KW) | |

| Flow@head | 2m3/h@8m | |

| Air Supply | Air compressor | V-0.25/8 (2.2KW) |

| Exhaust volume | 0.25m3/min | |

| Grouting pump | Model | LGH75/100PI-E |

| Piston diameter | 100mm | |

| Piston stroke | 150mm | |

| Low pressure@Flow | 0-50bar@0-75L/min | |

| High pressure@Flow | 0-100bar@0-40L/min | |

| Power | 11Kw | |

| Dimension(without screw feeder) | 4770×2250×2370mm | |

| Weight | 3880Kg | |

| Note: We can customize automatic colloidal grout mixing plants according to your requirements. |

||

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS