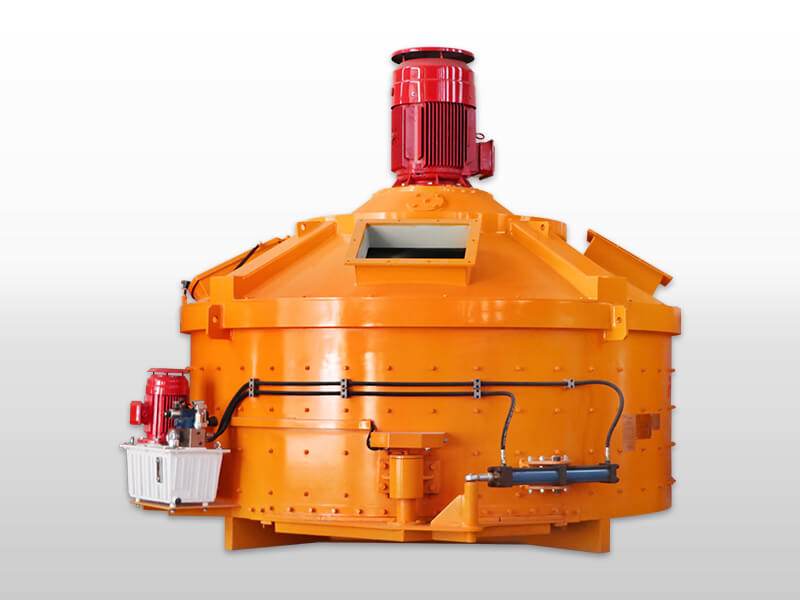

A broad spectrum of materials can be efficiently handled by our hydraulic discharging planetary concrete mixer, extending to both UHPC Ultra High-Performance Concrete and a variety of other construction and industrial applications.

Refractory Materials: Molded refractories, Unmolded refractories.

Concrete Products: Pre-mixed Concrete, Prefabricated Concrete, Foam Concrete, Colored Concrete, Lightweight Concrete, Spray-applied Concrete (Shotcrete).

Additional Building Components: Dry Mortar Mixes, Wet Mortar Mixtures, Gypsum Composites, Aggregate Blending, Emulsified Asphalt Processing, Cementitious Adhesives.

Miscellaneous Applications: Glass Manufacturing, Fertilizer Production, Water Treatment Processes, Mine Backfill Operations.

Our planetary concrete mixer is optionally equipped with a hydraulic discharge mechanism, allowing for full or partial opening of the discharge door. For added versatility, we also provide a hydraulic power unit that caters to dual discharge doors, enhancing the overall efficiency and adaptability to different mixing need.

► Features:

1. Employing a patented, specially designed high-strength and highly-reliable planetary reducer, ensuring exceptional durability and functionality.

2. Versatile design allows for flexibility in configuration, with options to incorporate 1-3 discharge doors to suit various production line requirements.

3. Ensures outstanding homogeneity during the mixing process for uniformity in the final product.

4. Features interchangeable wear-resistant liners secured with counter-sunk fixing bolts for easy replacement and extended service life.

5. Each moveable cover is fitted with an interlocking device and a safety switch to ensure maximum operational security.

6. Boasting a simple yet sturdy structure, this equipment ensures ease of maintenance and convenient upkeep, minimizing downtime and maximizing productivity.

Counter-current Gearing System

The rotation direction of mixing stars is reversed with the revolution direction, and each mixing star’s direction is also different. The circulation movement and convective movement make the material severely mix and achieve uniform distribution.

Convection Mixing Device

★High mixing efficiency, and low energy consumption.

★Compared with traditional planetary mixers, the mixing time of LCMP could be reduced by 15~20%.

★The no-load current and load current with the same material can be 15~20% lower.

Mixing Locus Diagrams

The diagram shows the perfect mixing action of the LCPM UHPC ultra high performance concrete planetary mixer from 6 to 60 seconds after the materials are added. Note that the floor is completely swept by the mixing star’s action every 4 revolutions (6 seconds) and that each zone is covered at regular intervals in time.

| Item | LCPM50 | LCPM100 | LCPM150 | LCPM250 | |||

| Feeding Volume (L) | 75 | 150 | 225 | 375 | |||

| Feeding Capacity (Kg) | 120 | 240 | 360 | 600 | |||

| Output Volume (L) | 50 | 100 | 150 | 250 | |||

| Mixing Power (Kw) | 3 | 5.5 | 7.5 | 11 | |||

| Mixing Star*Blade | 1*2 | 1*2 | 1*2 | 1*2 | |||

| Side Scraper | 1 | 1 | 1 | 1 | |||

| Discharge Scraper | - | - | 1 | 1 | |||

| Discharging Power (KW) | Pneumatic Discharging Door (Hydraulic Discharge Door Optional) | ||||||

| Weight (Kg) | 750 | 1000 | 1300 | 1500 | |||

| Item | LCPM330 | LCPM500 | LCPM750 | ||||

| Feeding Volume (L) | 500 | 750 | 1125 | ||||

| Feeding Capacity (Kg) | 790 | 1200 | 1800 | ||||

| Output Volume (L) | 330 | 500 | 750 | ||||

| Mixing Power (Kw) | 15 | 18.5 | 30 | ||||

| Mixing Star*Blade | 1*2 | 1*3 | 1*3 | ||||

| Side Scraper | 1 | 1 | 1 | ||||

| Discharge Scraper | 1 | 1 | 1 | ||||

| Discharging Power (KW) | Pneumatic Discharging Door (Hydraulic Discharge Door Optional) | ||||||

| Weight (Kg) | 2000 | 2400 | 3900 | ||||

Hydraulic discharge door optional UHPC ultra high performance concrete planetary mixer:

| Item | LCPM1000 | LCPM1250 | LCPM1500 |

| Feeding Volume (L) | 1500 | 1875 | 2250 |

| Feeding Capacity (Kg) | 2400 | 3000 | 3600 |

| Output Volume (L) | 1000 | 1250 | 1500 |

| Mixing Power (Kw) | 37 | 45 | 55 |

| Mixing Star*Blade | 2*3 | 2*3 | 2*3 |

| Side Scraper | 1 | 1 | 1 |

| Discharge Scraper | 1 | 1 | 1 |

| Discharging Power (Kw) | 3 | 3 | 3 |

| Weight (Kg) | 5500 | 6000 | 6500 |

| Item | LCPM2000 | LCPM2500 | LCPM3000 | LCPM4000 |

| Feeding Volume (L) | 3000 | 3750 | 4500 | 6000 |

| Feeding Capacity (Kg) | 4800 | 6000 | 7250 | 9600 |

| Output Volume (L) | 2000 | 2500 | 3000 | 4000 |

| Mixing Power (Kw) | 75 | 90 | 110 | 132 |

| Mixing Star*Blade | 3*3 | 3*3 | 3*3 | 3*3 |

| Side Scraper | 1 | 1 | 1 | 1 |

| Discharge Scraper | 2 | 2 | 2 | 2 |

| Discharging Power (Kw) | 4 | 4 | 4 | 4 |

| Weight (Kg) | 9200 | 11000 | 12000 | 17500 |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS