► Description:

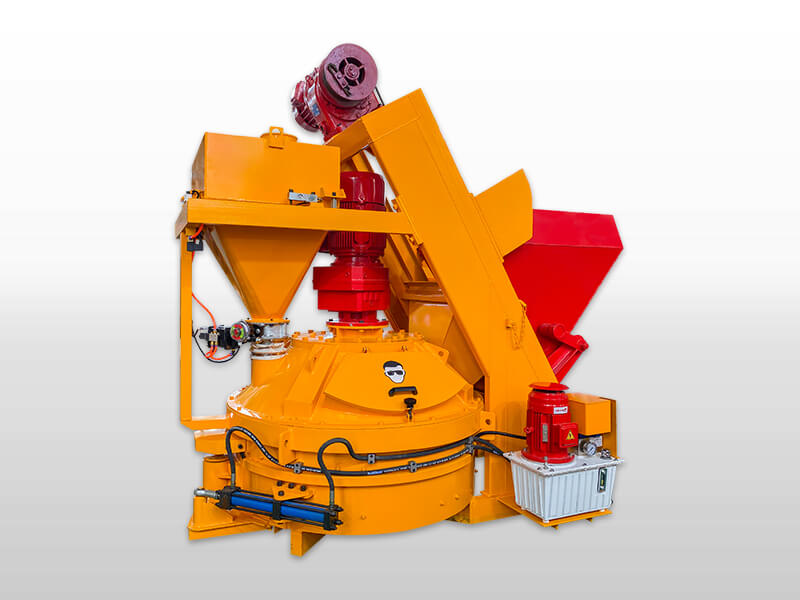

LCPM Planetary concrete mixer with lift skip hoist provides a reliable solution for producing concrete mixtures with high homogeneity and workability, it can mix all kinds of high-quality and high-performance concrete, and which can reach homogenous mixing at shortest time.

Planetary concrete mixer with lift skip hoist uses star-shaped rotating paddles to provide high-quality mixing for all types of concrete such as precast concrete, ready mix concrete, fiber reinforced, self-compacting concrete and other aggregates. Planetary mixers are widely used by preform producers to achieve greater uniformity and provide long-lasting performance.

The feed door opens automatically when feeding, and closes automatically when the hopper starts to descend. This device effectively prevents the dust from overflowing the trough during the mixing process and protects the environment. With an output capacity ranging from 5L to 5000L, the LCPM planetary concrete mixer with a lift skip hoist is suitable for a wide range of applications.

► Application:

LCPM series planetary concrete mixer with lift skip hoist is mainly used for mixing various building materials such as concrete, ultra-high performance concrete (UHPC), refractory materials, castables, etc., as well as metallurgy, glass production, chemical manufacturing and other industries.

► Features:

1. Weighing Sensor. Adopt famous brand pull-type or pressure sensors to achieve stable performance and high measurement accuracy.

2. SEW motor(Optional). All models above 2 m3 output are operated by Variable Frequency Drive (V.F.D.). 45-70° incline ( custom made ) Standard: 60°

3. Water Dosing System. Water measurement can use weighing methods: time control method, flow meter pulse method. High measurement accuracy and strong reliability.

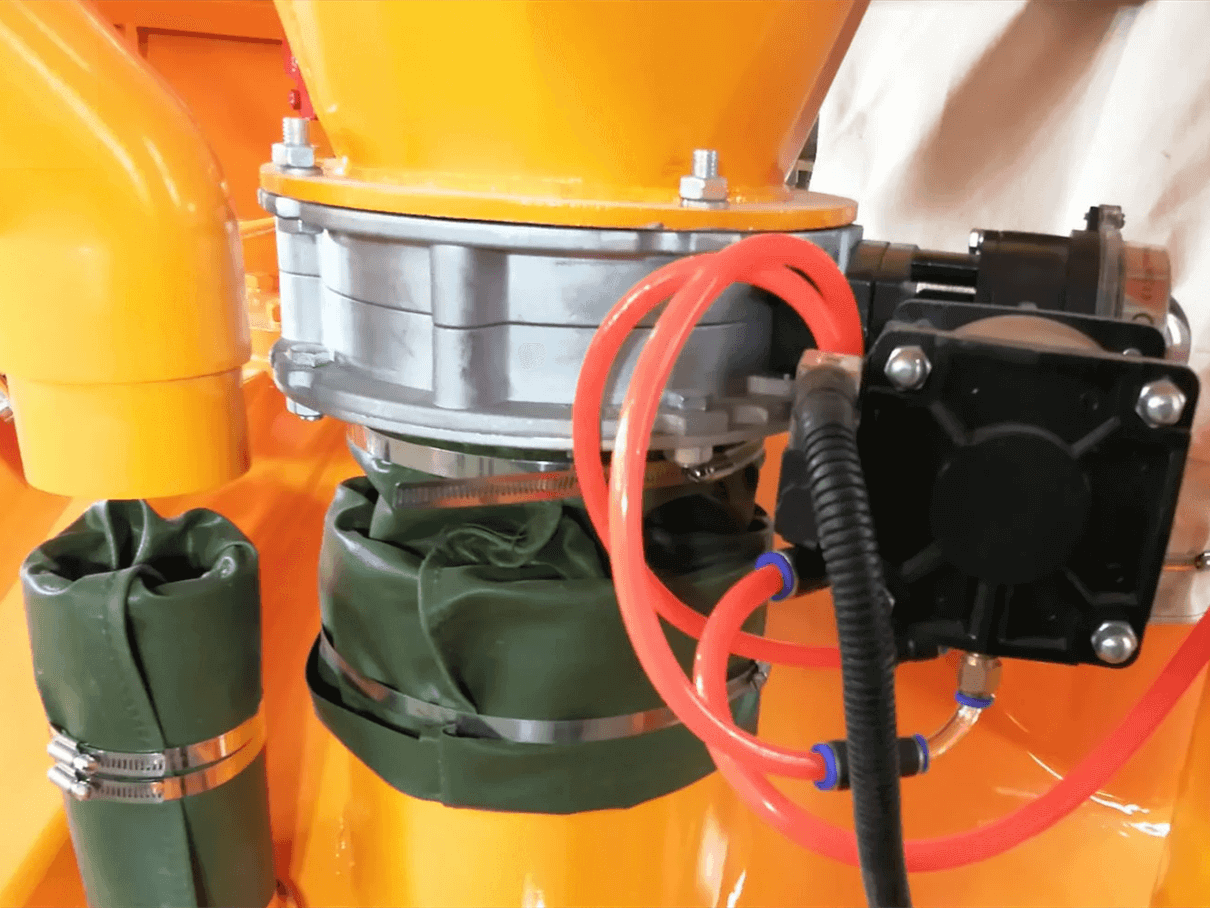

4. Butterfly Valve. Our pneumatic rubber-lined butterfly valve has good sealing performance and reliable performance and can transmit the signal of opening in place and closing in place.

5. Dust Remove System. The planetary concrete mixer with lift skip hoist can be equipped with a special dust removal device, and pulse back-flushing dust removal system. Filter and bag types can be chosen.

6. Powder Weighing System. The powder weighing system adopts a weight sensor for weighing and is equipped with a ventilation device, which has high measurement accuracy and strong stability.

| Item | LCPM50 | LCPM100 | LCPM150 | LCPM250 | LCPM330 |

| Feeding Volume (L) | 75 | 150 | 225 | 375 | 500 |

| Feeding Capacity (Kg) | 120 | 240 | 360 | 600 | 790 |

| Output Volume (L) | 50 | 100 | 150 | 250 | 330 |

| Mixing Power (Kw) | 3 | 5.5 | 7.5 | 11 | 15 |

| Mixing Star*Blade | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 |

| Side Scraper | 1 | 1 | 1 | 1 | 1 |

| Discharge Scraper | - | - | 1 | 1 | 1 |

| Discharging Power (KW) | Pneumatic Discharging Door (Hydraulic Discharge Door Optional) | 2.2 | 2.23 | ||

| Weight (Kg) | 750 | 1000 | 1300 | 1500 | 2000 |

| Item | LCPM500 | LCPM750 | LCPM1000 | LCPM1250 | LCPM1500 |

| Feeding Volume (L) | 750 | 1125 | 1500 | 1875 | 2250 |

| Feeding Capacity (Kg) | 1200 | 1800 | 2400 | 3000 | 3600 |

| Output Volume (L) | 500 | 750 | 1000 | 1250 | 1500 |

| Mixing Power (Kw) | 18.5 | 30 | 37 | 45 | 55 |

| Mixing Star*Blade | 1*3 | 1*3 | 2*3 | 2*3 | 2*3 |

| Side Scraper | 1 | 1 | 1 | 1 | 1 |

| Discharge Scraper | 1 | 1 | 1 | 1 | 1 |

| Discharging Power (Kw) | 2.2 | 3 | 3 | 3 | 3 |

| Weight (Kg) | 2400 | 3900 | 5500 | 6000 | 6500 |

| Item | LCPM2000 | LCPM2500 | LCPM3000 | LCPM4000 |

| Feeding Volume (L) | 3000 | 3750 | 4500 | 6000 |

| Feeding Capacity (Kg) | 4800 | 6000 | 7250 | 9600 |

| Output Volume (L) | 2000 | 2500 | 3000 | 4000 |

| Mixing Power (Kw) | 75 | 90 | 110 | 132 |

| Mixing Star*Blade | 3*3 | 3*3 | 3*3 | 3*3 |

| Side Scraper | 1 | 1 | 1 | 1 |

| Discharge Scraper | 2 | 2 | 2 | 2 |

| Discharging Power (Kw) | 4 | 4 | 4 | 4 |

| Weight (Kg) | 9200 | 11000 | 12000 | 17500 |

+86-18538591025

+86-18538591025 sales@leadcrete.com

sales@leadcrete.com 中文

中文 English

English Your Position:

Your Position:

(Live chat)

(Live chat)

.jpg)

.jpg)

Phone/Wechat

Phone/Wechat Whatsapp

Whatsapp

ADDRESS

ADDRESS